-40%

EPEVER MPPT Charge Controller 60A 48v/36v/24v/12v Solar Panel Regulator

$ 137.27

- Description

- Size Guide

Description

★EPever MPPT Solar Charge Controller 60Amp (Tracer6415AN ), 12V/24V/36V/48V Auto identifying system voltage , Max PV 150V , Common Negative Ground. Auto control system to limit the charging power & current go over the rated value.★Max Input Current: 60 amp, Max Input Solar panels Power: 750W/12V; 1500W/24V; 2250W/36V; 3000W/48V; Real-time energy recording and statistical.

★Support Lead-acid & Lithium types of Battery charging : Lead-acid (Sealed, AGM, Gel, Flooded) and Lithium Battery :LiFePO 4 / Li(NiCoMn)O 2 / User. Battery temperature compensation function to ensure the battery’s life.

★RS-485 communication bus interface and Modbus communication protocol, available to meet various communication requirements in different situations.

★ MPPT Solar controller 60A with high quality & low failure rate components of ST and Infineon and Battery temperature compensation function to ensure the controller’s life.Real-time energy recording and statistical.

EPEVER MPPT Solar Charge Controller 60A kit ( Tracer6415AN ) ,12V/24V/36V/48V DC auto work ,Max PV 150V , Common negative ground .

Based on common negative design and advanced MPPT control algorithm MPPT Charge efficiency > 99%.

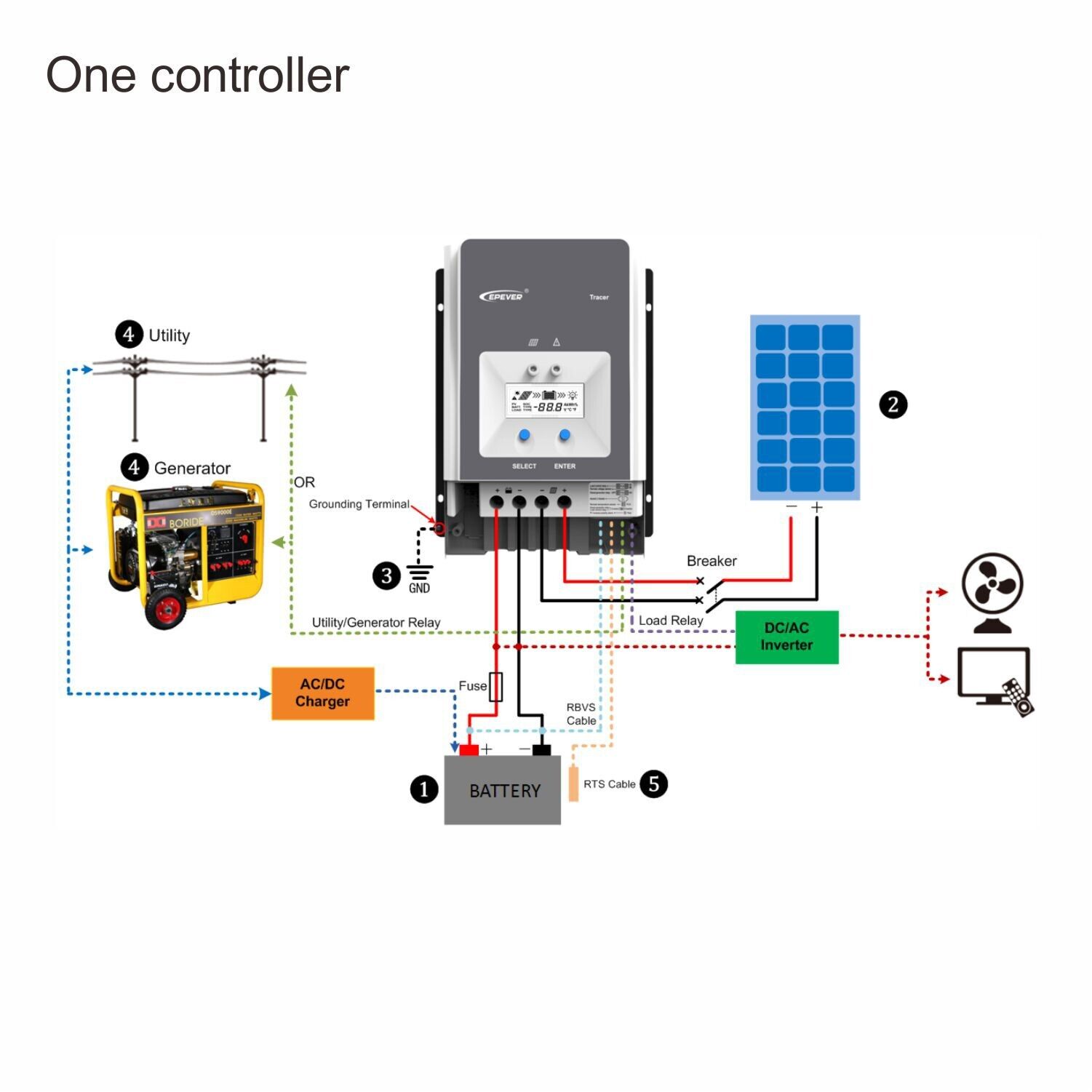

With the adaptive three-stage charging mode based on digital control circuit, Tracer AN series controllers can effectively prolong the life-cycle of battery and significantly improve the system performance. The load, utility or generator auto-control relays make it easy to compose the hybrid power system.

All-around electronic protections, including overcharging, over discharging, and PV reverse polarity protection, effectively ensure the safer and more reliable operation of the solar system for a longer service time. The isolated RS485 interface with standard MODBUS communication protocol and 5V power supply makes it easy for customer to expand the application.

It support up to 8 charging in parallel to expand system and meet with different monitoring requirements, so that can be widely used for various applications, e.g. solar RV, household system and field monitoring, etc.

Technical Data:

Nominal system voltage:12V/24V/36V/48V DC auto work

Rated charge current :60 Amp

Max. PV open circuit voltage:150V(at minimum operating environment temperature) 138V(at 25℃ environment temperature)

MPP voltage range:V(BAT)+2V~108V

Max. PV input power: 750W/12V, 1500W/24V, 2250W/36V ,3000W/48V

Tracking efficiency : ≥99.5%

Max. conversion efficiency :98.1%

Battery type : Lead-acid (Sealed, Gel, AGM, Flooded) and Lithium Battery: LiFePO4 / Li(NiCoMn)O2 / User. Battery temperature compensation function to ensure the battery’s life.

Battery input voltage range: 8--68V

Temperature: -20°C -- +70°C/-4°F -- 158°F

Grounding : Common negative grounding

Relay: Rated Value:5A/30VDC; Max. Value:0.5A/60VDC

RS485 interface: RS485(RJ45)

Power terminals:#2 AWG(35mm2)

Recommended cable:#6 AWG(16mm2)

Dimension:340*236*119mm

weight :4.5 KG

Package List:

1 X Tracer6415AN MPPT Solar Charge Controller

1 X Manual (English)

Note :Fast shipping from Chicago IL warehouse , our professional technical engineer could supply solar system solutions for you in time .

Support Max 8-Multiple units work in parallel

Battery types:

Sealed (default)/ Gel/ Flooded ,LiFePO4 , Li (NiCoMn)O2 ,

(

default parameters

);

User

type

could be setting by controller buttons ; more parameters setting need EPEVER accessories : MT50 , WiFi adapter , BLE adapter, eLOG01, PC software ;

Note: The following accessories are not included in controller box , you could check and purchase accessories separately .

Step:

Connect solar system in the order of 1.battery--> 2. load--> 3.PV array ; and disconnect solar system in the reverse order 3~2~1

Battery must be connected with controller first ! Never connect soalr panel array to controller Without/Before connect battery.

DO NOT connect any inverter/wind/Alternator or Charger into the charge controller directly ! You should connect with battery and add fuse .

If there is a long distance between the PV array and controller or between the controller and battery, larger size wires should be used to reduce the voltage drop and improve performance. (Recommended wire size is only for reference.)